CARRIAGE BOLT NOZZLES

Purchasing prefabricated, one time use, motor nozzles from vendors such as RCS represents a significant portion of the expense associated with building rocket motors. Even reusable nozzles such as those machined from graphite are initially quite expensive. After much thought it occurred to me that simple hardware store carriage bolts might be used to prepare reusable motor nozzles. Standard hardware shelf carriage bolt sizes proved to be very compatible in matching up with Aerotech/Dr. Rocket, etc. type motor casings and closures. It turns out that the head diameter of a carriage bolt is roughly twice the diameter of the threaded shaft of the bolt. Thus a 1/2" carriage bolt has a ~1" head, and so on. Carriage bolts can be purchased, off the shelf, in sizes up to 3/4" shaft. Thus one is not able to purchase carriage bolts for use in 54 mm and larger motors. I have prepared carriage bolt nozzles in all smaller motor sizes. The nozzles I have prepared to date have not been prepared with precision in mind. My drill press and other tools are not top of the line. I have, however, had excellent success in the use of the nozzles I have prepared even if their efficiency is not as great. Their preparation and use are outlined below. I have found that the use of stronger walled paper/phenolic motor liners are required so that strong compression of the carriage bolt head down onto the O-ring can be achieved without crumpling the liner.

Step 1. Trim bolt shaft to desired length

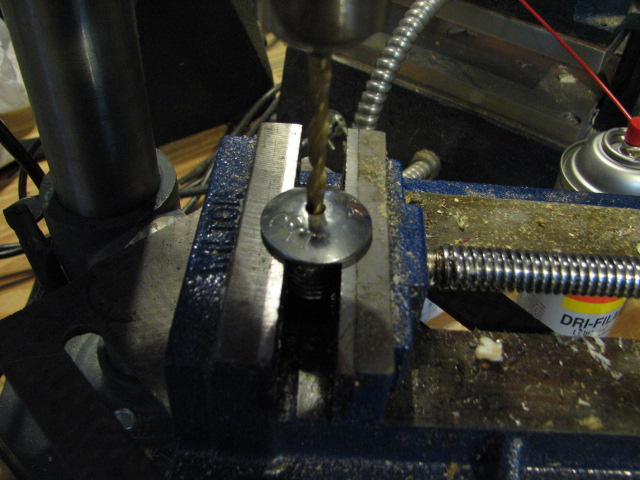

Step 2. Mark bolt head center and drill

a hole corresponding to your

desired nozzle throat size

length wise through the bolt.

Step 3. Use large drill bit to form nozzle

convergent slope.

Step 4. Using increasingly larger drill

bits prepare a divergent,

stepped cone for improved

combustion gas escape.

One Inch drill bit for convergent slope

Stepped cone divergent exaust

38mm

29mm

18mm

Step 5. Assemble in Motor

1. Standard O-ring-on-washer configuration

1

2

2. Nozzle resting on O-

ring

3. Screw on forward

closure until strong

o-ring compression is

obtained.

3

If a particular carriage bolt is slightly larger in diameter than the motor case, the diameter can be ground down for a loose fit. The corners of the metal square located at the interface of the shaft and flat underside of the head may need to be ground away in order for the motor forward closure to screw in far enough to apply flat, equil pressure to the smooth, level area of the underside of the bold head. Any raised letters on top of the bolt head should be ground down level with the rest of the head. The o-ring upon which the nozzle rests needs to be thick enough in diameter that the nozzle head does not come in contact with the insulator washer or propellant grain once the appropriate amount of o-ring compression via forward closure is applied.

Bolt and O-Ring Sizes

38mm -- 5/8 & 318

29mm -- 1/2 & 212

24mm -- 7/16 & 115

18mm -- 5/16 & 111